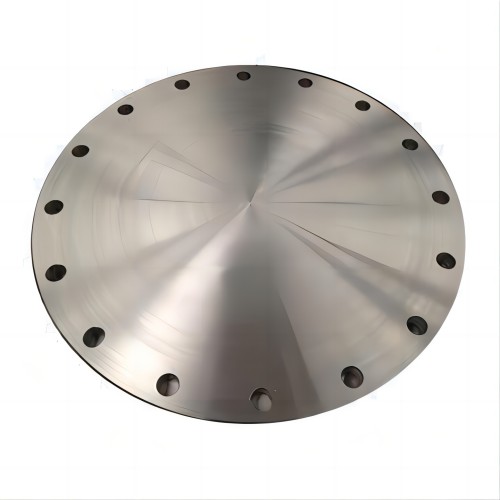

Carbon Steel Welding Neck Flange A105 Forged

Product Data

| Product Name | Welding Neck Flange | ||||||||

| Size | 1/2"-24" DN15-DN600 | ||||||||

| Pressure | Class150lb-Class2500lb | ||||||||

| PN10,PN16,PN25,PN40 | |||||||||

| Numbers of Holes | 4--20 | ||||||||

| Standred | ANSI | ANSI B16.5, ASME B16.47 series A/B | |||||||

| DIN | DIN2632/2633/2634/2635 | ||||||||

| GOST | GOST 12821/33259 | ||||||||

| EN1092-1 | EN1092-01 | ||||||||

| JIS | JIS B 2220, JIS B2238 | ||||||||

| BS | BS4504 BS10 BS3293 | ||||||||

| SANS | SANS1123 | ||||||||

| Technology | Forged,Cast | ||||||||

| Material | Carbon Steel ASTM A105 ST37.0 A350 LF2 A694 F60 A694 F70 | ||||||||

| Sealing Surface | FF、RF、M、FM、T、G、RJ | ||||||||

| Applicable Medium |

oil,gas,water or other medium | ||||||||

| Application | Petrochemical industry;Aviation and aerospace industry;Pharmaceutical industry;Gas exhaust;Power plant;Ship building;Water treatment,etc. | ||||||||

Product Introduction

Carbon steel is an alloy consisting primarily of carbon and iron, usually with low levels of alloying elements. Its main feature is that it has high strength and hardness under certain conditions, and it is relatively easy to process and low in cost. Carbon steel is one of the most common types of steel and is widely used in various fields.

The characteristics and classification of carbon steel are as follows:

1. Composition: Carbon steel is mainly composed of iron and carbon, and the carbon content is generally between 0.1% and 2.0%. In addition to carbon, it may also contain a small amount of silicon, manganese, phosphorus, sulfur and other elements.

2. Strength: The strength of carbon steel is usually higher and has better mechanical properties. This makes carbon steel widely used in fields such as structure, construction and machinery manufacturing.

3. Hardness: The hardness of carbon steel can be controlled by adjusting the carbon content, from softer low-carbon steel to harder high-carbon steel.

4. Machinability: Since carbon steel contains less alloying elements, it is relatively easy to process and form, and can be used to manufacture products of various complex shapes.

According to the carbon content and characteristics of carbon steel, carbon steel can be divided into the following categories:

1. Low carbon steel: the carbon content is between 0.05% and 0.30%. It has good plasticity and weldability, and is used to make cold-drawn steel wires, cold-pressed parts, etc.

2. Medium carbon steel: the carbon content is between 0.30% and 0.60%. It has certain strength and wear resistance, and is often used in the manufacture of mechanical parts such as gears and crankshafts.

3. High carbon steel: the carbon content is above 0.60%. It has high hardness and strength, but poor plasticity, and is usually used to make knives, springs and bearings.

4. Ultra-high carbon steel: the carbon content is above 2.0%, very hard and brittle. This steel is often used for special tools or knife edges, but due to its brittleness, its range of applications is limited.

It is important to note that carbon steel is susceptible to oxidation and rust due to its lack of corrosion resistance. Therefore, in some applications, other materials such as stainless steel are selected to meet special requirements.

Weld neck flange is a common pipe connection flange used to connect different parts of the piping system, such as pipes, valves, equipment, etc. It has the characteristics of a neck, also known as a neck flange.

The following is an introduction to the weld neck flange made of carbon steel:

1. Structural features: The main components of the neck butt welding flange include the flange plate and the flange neck. Flanges are round flat plates used to connect with connected pipes and equipment. The flange neck is the protruding part connected to the flange, usually connected to the pipe by butt welding. The diameter and thickness of the flange neck are usually determined according to the pressure rating and size of the pipe.

2. Material: Carbon steel is a common material choice, especially suitable for general industrial applications, such as piping systems conveying non-corrosive fluids or gases.

Carbon Steel Weld Neck Flanges are widely used in general engineering projects, making them an economical and practical choice due to their strength and machinability.

3. Application scenarios: Weld neck flanges are usually used in high-pressure and high-temperature piping systems, as well as occasions that have high requirements for piping connections. Its design can reduce the resistance of the fluid at the pipeline connection, while providing a certain degree of rigidity and sealing performance, so it is widely used in some process pipelines and important equipment connections.

4. Installation: When installing the butt welding flange with neck, first align the connection between the flange and the pipe, and then fix the flange neck with the pipe by welding to form a firm structure. Next, on the other side of the flange, the two flanges are tightly pressed together by bolts to achieve the sealing of the pipe connection.

Generally speaking, carbon steel neck butt welding flange is a common and economical and practical pipe connection method, which is suitable for general industrial and engineering projects. When selecting and using, it is necessary to make a reasonable selection according to the specific piping system requirements and working conditions to ensure the reliability and safety of the connection.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top