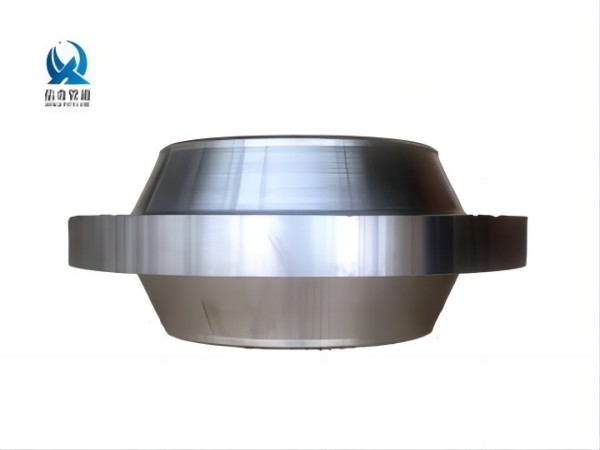

Stainless Steel 304 316 316L Anchor Flange ANSI, DIN, GB, JIS, GOST TP304 12X18H10T 1.4301/1.4307

Picture Presentation

Product Data

| Product Name | Stainless Steel Anchor Flange | |||||||

| Size | 1/2"-24" | |||||||

| Pressure | 150lb, 300lbs,600lb, 900lb, 1500lb,2500lb | |||||||

| Standard | ANSI B16.5 ,ANSI B16.47 | |||||||

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. | |||||||

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. | |||||||

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | ||||||||

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | ||||||||

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | ||||||||

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | ||||||||

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | ||||||||

| Application | Petrochemical industry;avation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship buliding;water treatment,etc. | |||||||

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality | |||||||

Product Introduction

Anchor Flange is a flange used to connect pipelines and equipment. It has the function of anchoring and fixing pipelines and can be used to connect pipelines and equipment in high temperature, high pressure or high vibration environments. Anchor flanges usually consist of two parts, one is the flange itself, and the other is the anchor rod used to fix the pipe. The following is a detailed introduction of the anchor flange:

Anchor flanges are mainly composed of flanges, anchor rods and bolts. The flange part includes a flange with a hole and a flange with a flange, and the two flanges are connected by bolts and gaskets. Anchor rods are usually made of steel rods and are passed through the pipe through the hole in the flange and fixed to the equipment.

Size

The size and standard of the anchor flange are determined by the design and manufacturing standards, the most common standards are ASME B16.5 and ASME B16.47, etc. The size of the anchor flange can be selected according to the size and pressure rating of the pipeline.

Pressure Level

The pressure rating of the anchor flange can be selected according to the pressure of the pipeline. Common pressure ratings include Class 150, Class 300, Class 600, Class 900 and Class 1500, etc.

How to use

The use of anchor flanges is mainly to fix pipes and equipment together through anchor rods. First, connect the flanges with the pipe, and place an appropriate number of gaskets between the flanges. Then, thread the anchor through the hole in the flange and secure it to the unit on the other side. Finally, by tightening the bolts, the gasket between the flanges is squeezed, creating a tight seal.

Applications

Anchor flanges are mainly used to connect pipelines and equipment with high temperature, high pressure or high vibration. They are commonly used in industries such as the oil and gas industry, chemical industry, power plants, nuclear power plants, paper mills and shipyards. Because the anchor flange has excellent pressure and vibration resistance, it can ensure the safe and stable operation of pipelines and equipment.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top