What is a stub end? How should it be used? Under what circumstances do you use it? People often have such questions, let’s discuss them together.

The stub end is often used together with the lap joint flange to form a substitute for the welding neck flange connection, but remember that it cannot be used as a welding neck flange, and they cannot be confused.

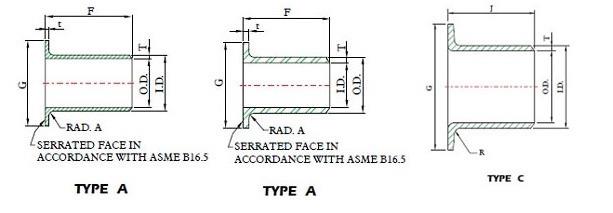

STUB END TYPES

There are three common types of stub end, namely type A, type B and type C

1. The type A is manufactured and machined to match standard lap joint flange (the two products have to be used in combination).

The mating surfaces have an identical profile to permit a smooth loading of the flare face

2.The type B has to be used with standard slip-on flanges

3. The type C can be used either with lap joint flange or slip-on flanges and are manufactured from pipes

There are two types of stub end, short and long, and its maximum size can reach 48 inches, that is, various models of DN15-DN1200.

The short pattern, called MSS-A stub ends

The long pattern, called ASA-A stub ends or ANSI length stub end.

ADVANTAGES OF STUB ENDS

1. The stub end can reduce the total cost of the flange joint of the high material grade piping system, because the lap flange does not have to use the same material as the pipe and the short end, and a lower grade material can be selected for matching.

2.Stub end speeds up the installation process because the lap flanges can be rotated for easy alignment of the bolt holes.

Stub ends can be ordered with different ends finishing

- Beveled Ends

- Squared Ends

- Flanged Ends

- Grooved Ends

- Threaded Ends

APPLICATION

1.The stub end, which is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same bore size, material and wall thickness.

2.A lap joint flange, which is used to actually bolt the two lengths of pipe together.

Post time: Jun-06-2023