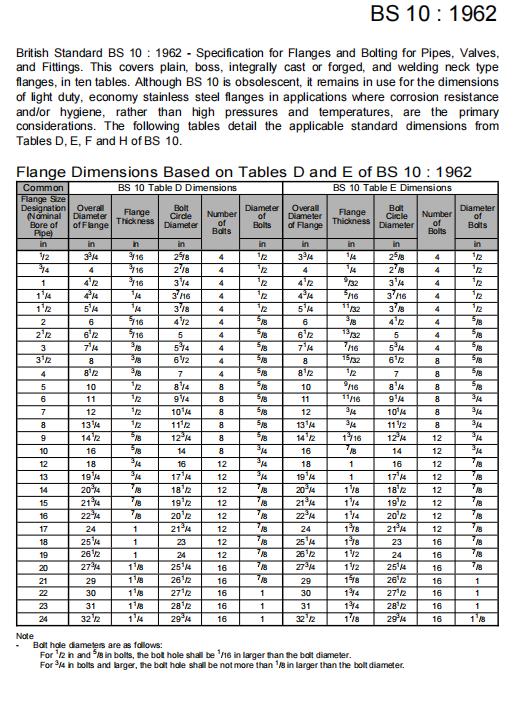

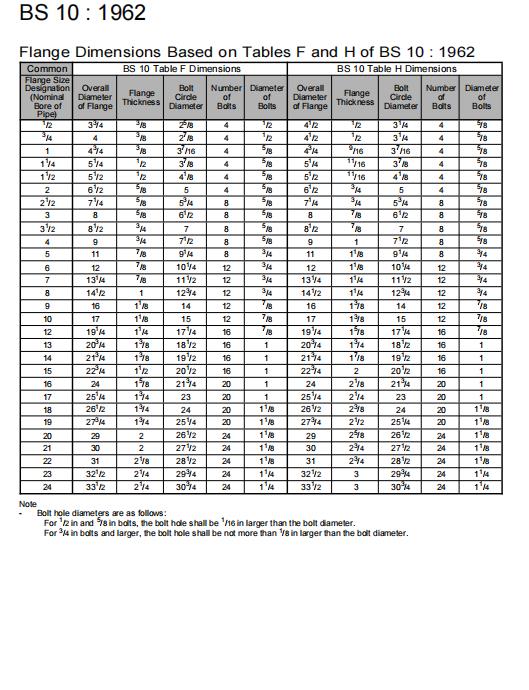

The size representation of BS10 is different from other American and British standards. BS 10 uses Table D, Table E, Table F and Table H to represent dimensions.

BS10 flange standard is mainly used for blind flange, slip on flange and welding neck flange.

The blind flange plays the same role of isolation and cutting off as the head and pipe cap. Because of its good sealing performance, it is generally used as a reliable means of isolation for systems requiring complete isolation. The blind plate is a solid circle with a handle, which is used for the system in the isolation state under normal conditions. The spectacle blind is shaped like a spectacle blind. One end is a blind plate and the other end is a throttling ring, but the diameter is the same as the pipe diameter and does not play a throttling role. The spectacle blind plate is easy to use. When isolation is required, use the blind plate end. When normal operation is required, use the throttling ring end. It can also be used to fill the installation gap of the blind plate on the pipeline. Another feature is obvious identification and easy to identify the installation status.

The rigidity of neck butt welding flange is higher than that of neck flat welding flange, and the strength of butt welding is higher than that of flat welding, so it is not easy to leak.

Butt-welding flange with neck and neck can not replace the flange for butt welding. From the manufacturing point of view, the inner diameter of the neck slip-on flange is larger. This means light weight and low cost. In addition, the neck butt welding flange with nominal diameter greater than 250 mm needs to be tested, while the flat welding flange does not need to be tested, so the cost is relatively low.

Post time: Feb-21-2023