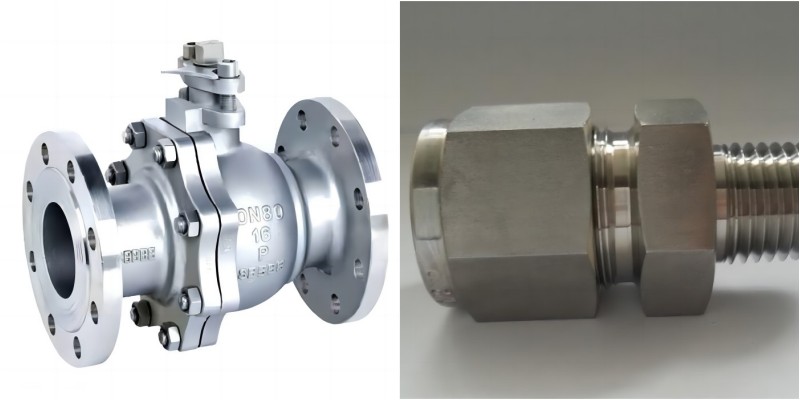

Threaded connection and flange connection are two different pipeline connection methods during the specific construction process.

Flange connection

The flange connection is composed of a pair of flanges, a gasket, and several bolts and nuts. Flange connection is a detachable connection.

Principle: It is a detachable joint that first fixes two pipes, fittings, or equipment to a flange, then adds flange pads between the two flanges, and finally tightens the two flanges with bolts to tightly connect them. It can achieve the connection between a stationary pipeline and rotating or reciprocating equipment

Performance: Good strength and sealing, simple structure, low cost, can be repeatedly disassembled, and has a wide range of applications.

Failure form: mainly manifested as leakage, with the leakage amount controlled within the allowable range of the process and environment.

Relevant reference:Purpose of flange

Threaded flange

A threaded flange is a non welded flange that processes the inner hole of the flange into a pipe thread shape and is connected to a threaded pipe. Compared with welded flanges, it has the characteristics of easy installation and maintenance, and can be used in some situations where welding is not allowed on site. However, when the temperature is above 260 ℃ and below -45 ℃, it is recommended not to use threaded flanges to avoid leakage.

How to differentiate:

1. Appearance: Threaded connections are usually cylindrical, with external threads on one end and internal threads on the other end. The flange connection is a flat circular or square interface with fixed bolt holes on it.

2. Connection method: The threaded connection requires rotating the two ports together until they are fully connected. The flange connection requires tightening the bolts of the two flanges and placing a sealing ring between the two flanges to ensure air tightness.

3. Scope of application: Threaded connections are suitable for low pressure and small diameter pipeline systems. And flange connection is suitable for high pressure and large diameter pipeline systems.

4. Installation and maintenance: Threaded connections are relatively easy to install and maintain, and can be quickly disassembled. However, flange connections require more time for installation and maintenance, and require more tools and labor.

5. Cost: Usually, threaded connections are cheaper than flange connections, which is also one of the reasons why they are widely used.

Overall, the choice of threaded connection or flange connection should be determined based on the pressure, diameter, and specific application requirements of the pipeline system.

Post time: Apr-13-2023