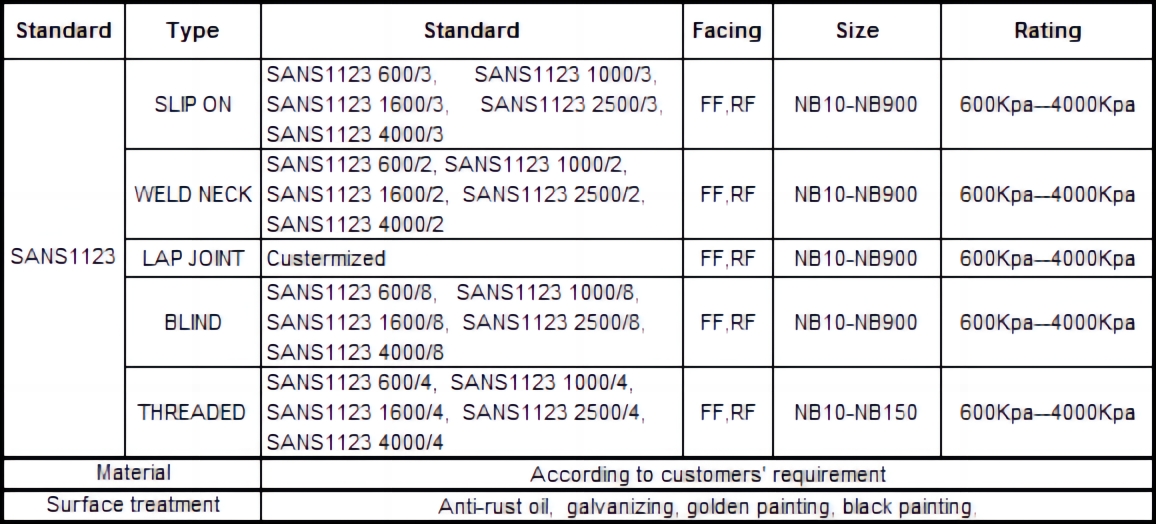

Under the SANS 1123 standard, there are several types of slip on flanges, welding neck flanges,lap joint flanges, blind flanges and threaded flanges.

In terms of size standards, SANS 1123 is different from common American, Japanese and European standards. Instead of Class, PN and K, the SANS 1123 adopts a special representation: For example, with neck flat welding flange 600/3, 1000/3, 1600/3, 250/3, 4000/3, with neck butt welding flange is different, 600/2, 1000/2, 1600/2, 250/2, 4000/2, Blind flange is 600/8, 1000/8, 1600/8, 2500/8, 4000/8, threaded flange is 600/4, 1000/4, 1600/4, 2500/4, 4000/4, loose flange can be customized size.

The SANS 1123 flange is close to the European flange marked with PN, and its pressure rating ranges from 250 kPa to 4000 kPa, which is converted to the pressure rating marked with PN, namely PN 2.5 to PN 40, but its applicable temperature is - 10 ℃ to 200 ℃, and the applicable temperature range is small. After verification, it was found that, compared with BS EN 1092-1 flange, under the same nominal size and corresponding pressure class, although some of the larger nominal size flanges of SANS 1123 flange are thinner, the flange outer diameter, bolt hole center circle diameter, fastener sets and thread specification, which determine whether the two flanges can be fixed by fasteners, are basically the same flange connection size, Therefore, SANS 1123 flange basically meets the requirements of various pipe material grades in this project.

Because the production technology level of South African steel pipes is generally behind that of developed countries in Europe and the United States, the technical indicators of steel pipes produced according to South African standards are low and the pressure bearing capacity is limited, the South African steel pipe standard of this project is only used for carbon steel pipes with low temperature and low pressure, and the carbon steel pipes with design pressure > 2.5 MPa or design temperature > 100 ℃ and all stainless steel pipes adopt American standards. The chemical composition and strength index of steel pipe materials in South African steel pipe standards and American steel pipe standards have certain differences, and some steel pipes have different outer diameters (see Table 1, such as DN65). Although the problem of the difference in the material composition of the steel pipe base material at both ends of the weld can be solved through the selection of welding rods and the improvement of welding process, and the problem of the difference in the outer diameter of the steel pipe at both ends of the butt weld can be solved through the staggered trimming, this undoubtedly brings great difficulties to the pipeline construction and is not conducive to the guarantee of construction quality. The sealing connection can be realized through the cooperation of flange, gasket and fastener. The gasket separates the flanges at both ends, and the fastener does not require the same material of the flanges at both ends. Therefore, the difference between the material composition and outer diameter of the steel pipes at both ends can be solved. After all, the connection of steel pipes with different standards usually occurs at the place where the pipe material grade changes. Such joints are not many, and the use of flanges will not add much cost to the project.

Post time: Mar-02-2023