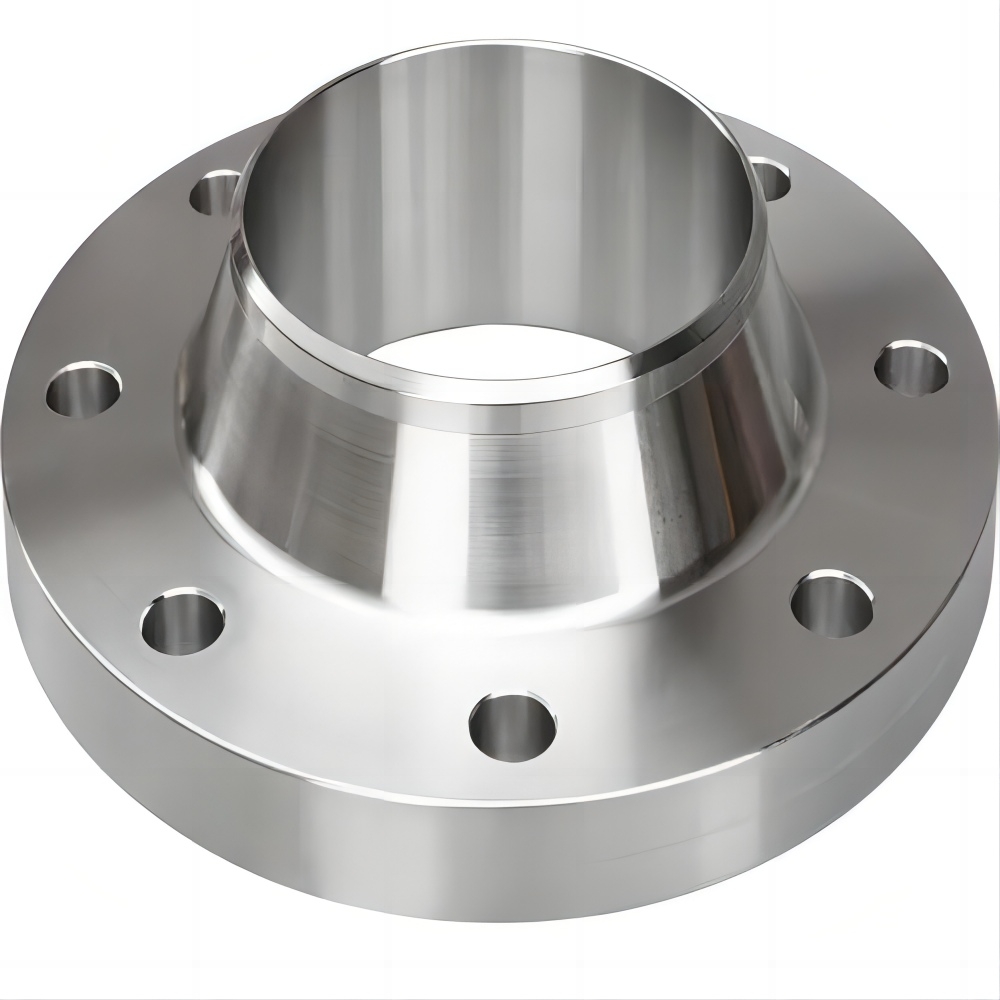

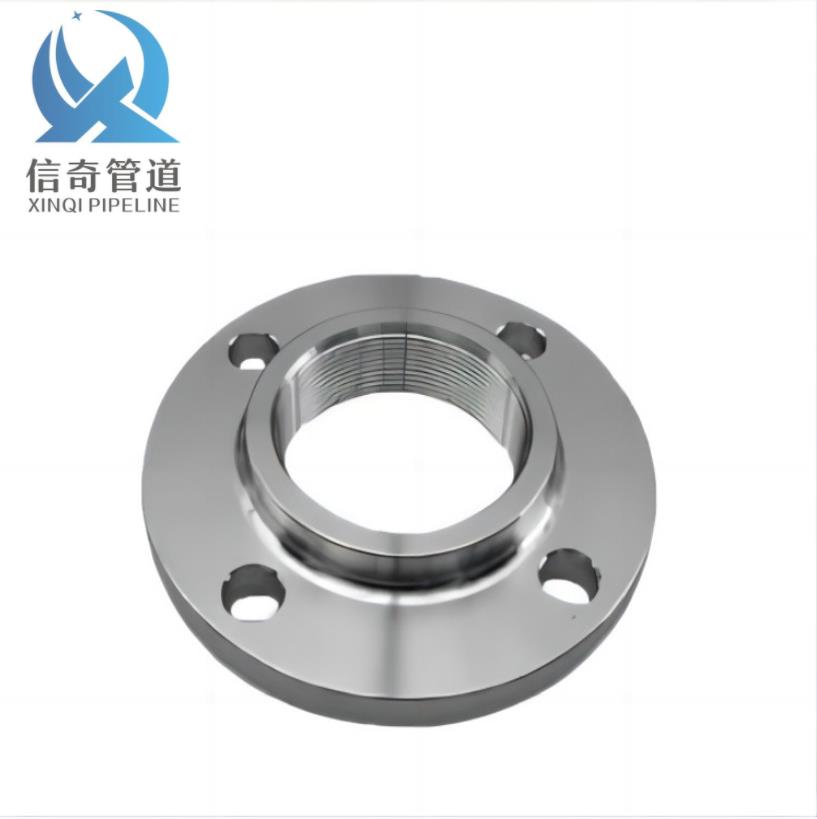

Aluminium 6061 Class 150 ANSI B16.5 Raised Face Slip-On Flange

Product Introduction

Aluminum alloy 6061 hubbed slip on flange is a flange connector made of aluminum alloy 6061, which has specific design and characteristics.

Aluminum alloy 6061 is an aluminum alloy with good general performance and is often used in various engineering applications. It has good strength, corrosion resistance and weldability. This alloy can provide the proper strength and reliability when making flanges, while maintaining a low density, which helps reduce the weight of the overall piping system.

Hubbed slip on flange: “Hubbed” means that the center portion of the flange has a raised annular neck. This neck acts as an anchor and support when the tubing is joined, helping to ensure that the tubing is properly aligned during the connection. The design of the neck can also provide extra strength to adapt to different application environments. And “flat welding” means that the flange can be connected with the pipe by welding. Slip-on flanges are made by welding the flange to the pipe to form a strong connection and are suitable for applications that require reliable sealing and strength.

Dimensions:

Dimensions of slip on flanges vary according to the standards being followed and specific project needs. Generally speaking, the dimensions include the outer diameter, inner diameter, neck diameter, screw hole diameter, number of screw holes, and hole pitch of the flange. These dimensions will affect the applicable range and connection method of the flange.

Advantages and disadvantages:

Advantage:

1. Lightweight and high-strength:

Aluminum alloy 6061 has good strength and light-weight properties, which helps to reduce the load on the piping system.

2. Corrosion resistance:

Aluminum alloy 6061 has good corrosion resistance and can be used in different environments.

3. Weldability:

Aluminum alloy 6061 is easy to weld and is suitable for flat welding flange connections.

4. Neck design:

The neck design of the neck flat welding flange can provide the positioning and support function of the pipeline connection.

5. Reliable sealing:

The connection of the flat welding flange has good sealing performance, reducing the risk of leakage.

Disadvantages:

1. Limited to low and medium pressure levels:

The strength of aluminum alloy is relatively low, so the aluminum alloy 6061 neck flat welding flange is suitable for low to medium pressure levels. In high pressure applications, other stronger materials may need to be considered.

2. Not suitable for high-temperature applications:

Aluminum alloys have limited high-temperature resistance, so their applications in high-temperature environments are limited.

3. Some corrosive media are not suitable:

Although aluminum alloy 6061 has certain corrosion resistance, its application in some strong corrosive media may be limited.

Application fields:

Aluminum alloy 6061 neck flat welding flanges are widely used in various industrial fields, such as:

1. Light industry: Including general pipeline connection, gas and liquid transmission, etc.

2. Oil and gas: For oil and gas pipelines, suitable for low to medium pressure levels.

3. Chemical industry: It is suitable for the transmission and treatment of some corrosive media.

4. Food processing: Used in food processing equipment and pipelines, due to the non-reactivity of aluminum, it is suitable for specific applications.

Please note that the specific application of aluminum alloy 6061 slip on neck flange will vary according to the needs of the project and the environmental conditions. When selecting and using this type of flange, it is necessary to carefully consider the material, design and connection method according to the engineering requirements.

In summary, aluminum alloy 6061 neck flat welding flanges have the advantages of light weight, high strength, corrosion resistance, weldability and neck design, etc., and are suitable for general engineering projects, especially for low and medium pressure levels and relatively mild environment applications. When selecting and using this type of flange, it is necessary to fully consider the needs of the project and engineering conditions to ensure that the appropriate material and design are selected.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top